LIMS for Quality Control labs

A laboratory information

management system provides services that support modern laboratory’s

operations. The services that are provided include data exchange interfaces

that provide complete support in current environments. The uses of a LIMS have

developed since the beginning from sample tracking to an enterprise resource

planning tool that manages multiple aspects of laboratory informatics. A LIMS

stays active and up to date because the laboratory’s requirements change at a

fast pace, and as a result LIMS attends to different needs for different

laboratories, making it an evolving concept. Laboratories depend on a LIMS to

manage data, assign rights, manage inventory, etc.

Having a LIMS software solutions can prevent laboratory equipment

from the error of maintenance or calibration which may not be possible to find

using a paper-based lab solution. In the event of equipment maintenance

malfunction, you would need to perform additional tests to prove that the

system was compatible. This may be time consuming and also expensive. Whereas,

a LIMS solution can avoid this by using its operations to send samples or

assign instruments that are already maintained in the approved manner and also

by managing maintenance scheduling. It also helps that LIMS platforms can be

arranged to assign work to those analysts that are experts in their field of

work.

Experts state that working

with paper-based systems for QA labs is no longer cost or time- effective,

though it exists in theory. The usage of analytics software helps analyze

results with a greater depth of business intelligence, extract historical data

to understand the beginning of issues and how they can be prevented.

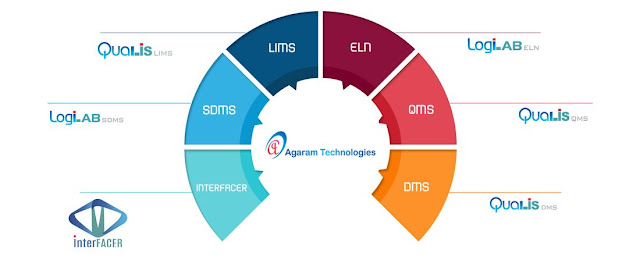

A LIMS solution that is built

for QC laboratory will deliver the functionality that is necessary to connect

several labs and instruments and combine with already existing enterprise

systems such as Quality Management Systems (QMS) and Manufacturing Execution

Systems (MES). This can help your lab with the processing and quality control

associated with the sample and the utilized equipment and inventory.

The bottom line is data

integrity and instrument integration. It is critical for any laboratory to

verify the quality standards for the product that they manufacture and that it meets

all the regulatory requirements. To achieve this, it is important for your data

to be original, accurate and contemporaneous.

Comments

Post a Comment